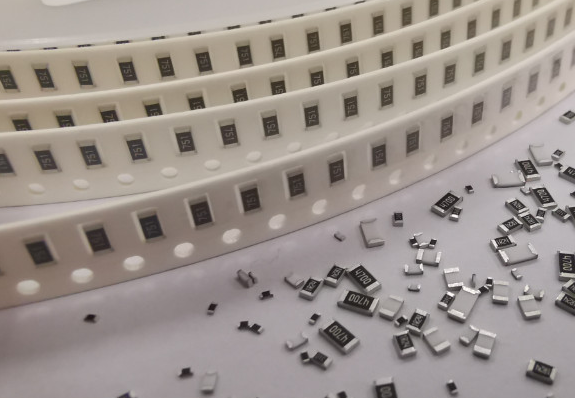

In the case of thin film chip resistors tfcr laser trimming is capable of delivering final post processing performance of the tfcr to within 0 02 percent of nominal value.

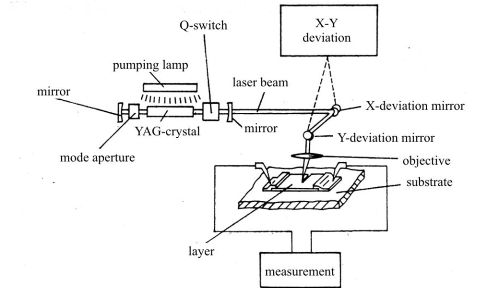

Laser based resistor trimming system.

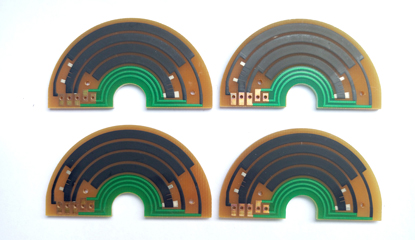

Laser trim marks are visible in the grey resistive material.

Ceramic backed with glass hermetic seal cover.

Supported by process development and customized tooling als300 lasers are a vital part of aurel turn key manufacturing solutions.

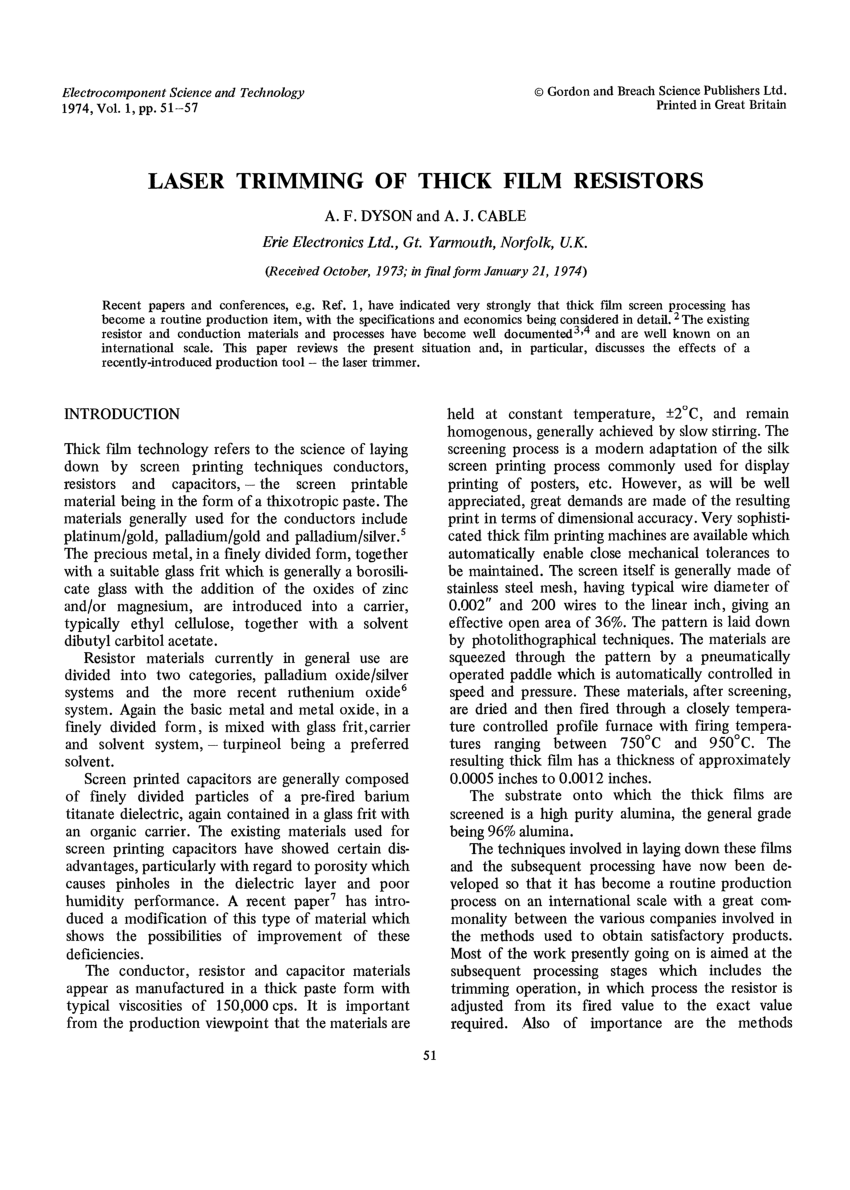

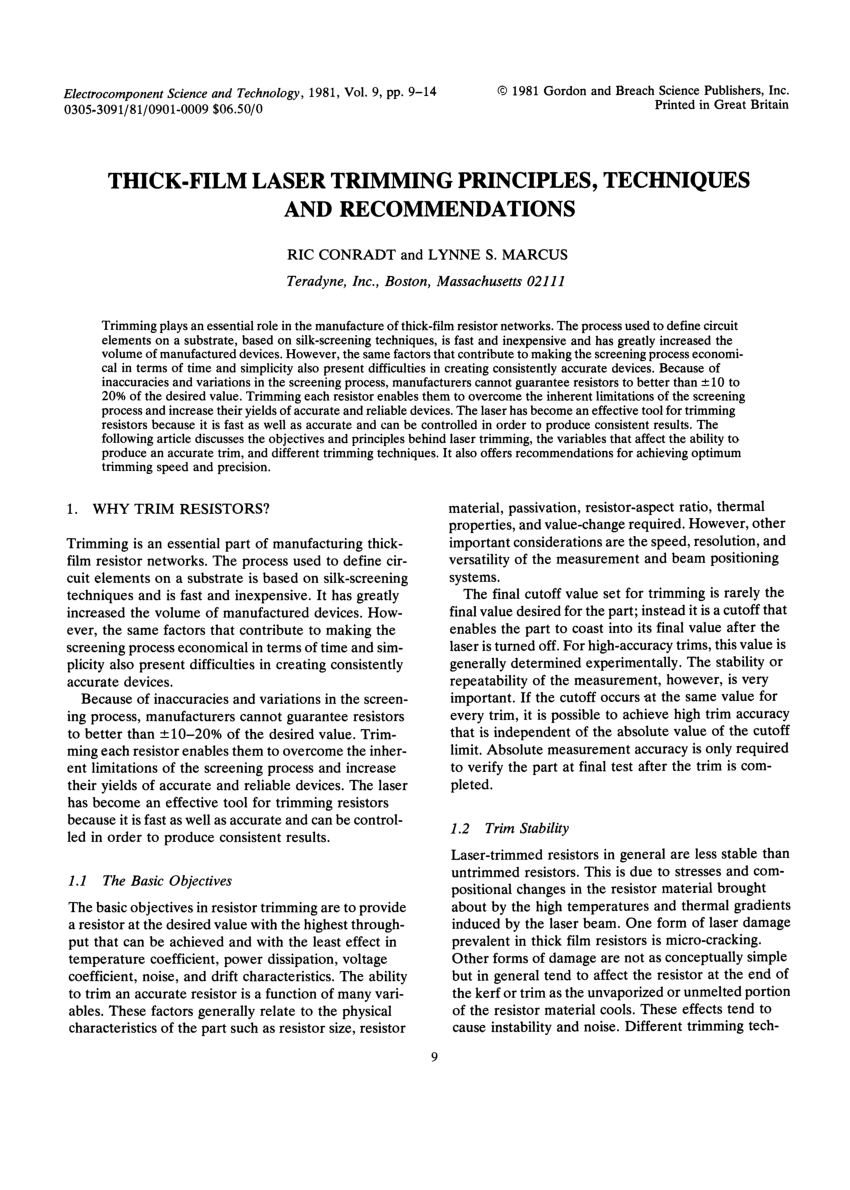

Laser trimming has become a successful and indispensable tool for the production of microelectronics devices where high precision and high performance are required.

Large board thick film resistor trimming is a specialty of laserod.

Upon job completion laserod will provide you with excel graphs that indicate your initial and final trim values for your comparison.

This makes this laser ideally suited for high speed resistor trimming applications.

Laser trimming is the manufacturing process of using a laser to adjust the operating parameters of an electronic circuit.

Additionally the jenlas comes with back reflection protection an on axis guide laser and both software and hardware control interfacing making the system easy to integrate into modern industrial process systems.

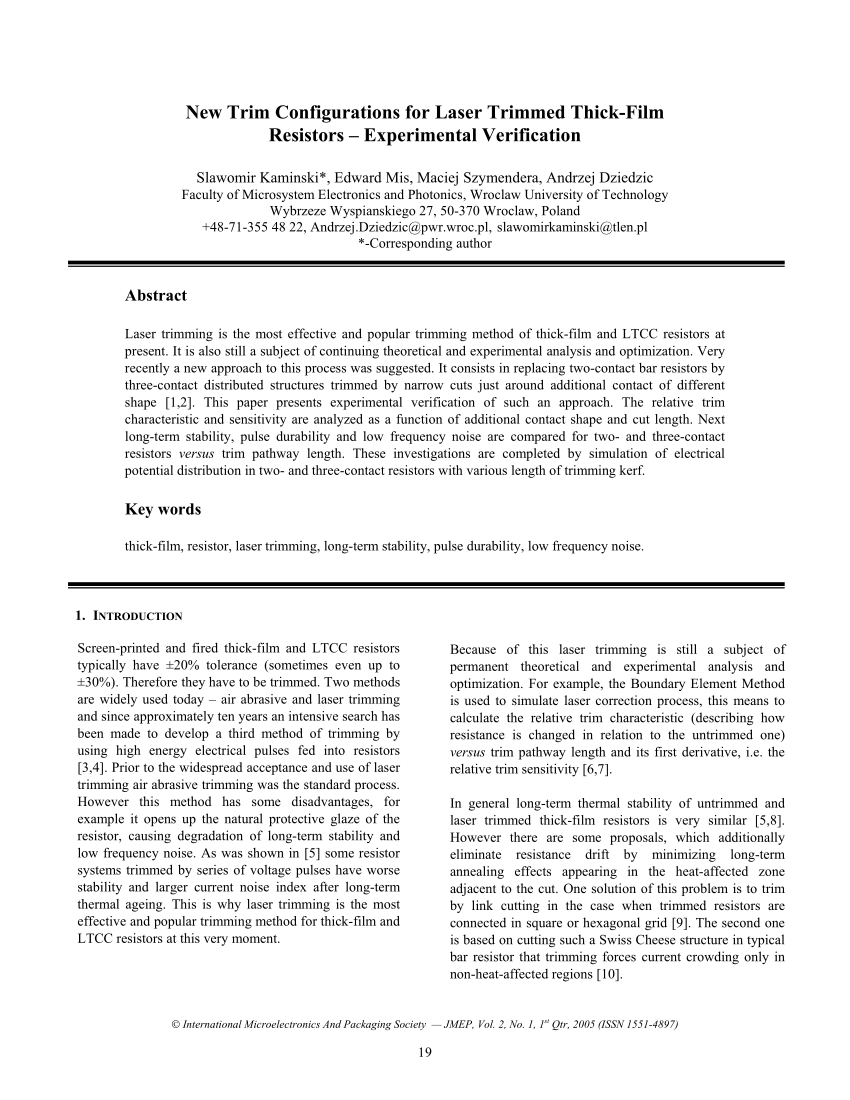

Resistor trimming hubrid circuits.

Laser trimmer als300 aurel als300 lasers are offered either as a basic system or with optional handling modules for integration into a customer s production line.

Board sizes to 24 x 24 or 36 x 24 are easily handled.

Sales of remanufactured esi laser trimming systems vje enterprises offers remanufactured esi model 44 model 80 and model 8000 laser trimming systems.