Several standards exist for laser weld quality not specifically relevant the most relevant en iso 13919 2 2001 welding electron and laser beam welded joints guidance on quality levels for imperfections part 2 relates to electron and laser beam welding of aluminium alloys.

Laser beam welding quality control.

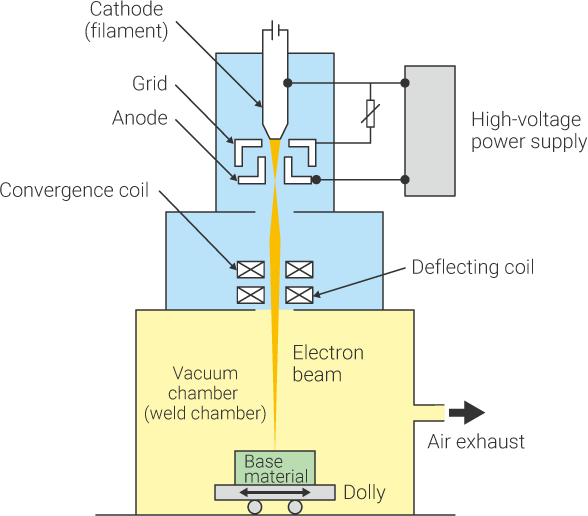

Electron beam engineering provides services throughout the u s a.

Electron beam welding machines are engineered for high performance with advanced computer controls data logging and beam control.

In the powder bed process one of the most common methods used in 3d metal printing a laser beam passes through a layer of metal beads and welds them together.

The monitoring process developed at empa can be used not only for laser welding but also for quality control of 3d printed metal parts.

Laser welding is fast becoming the preferred technique for joining various materials together and plastics are no exception.

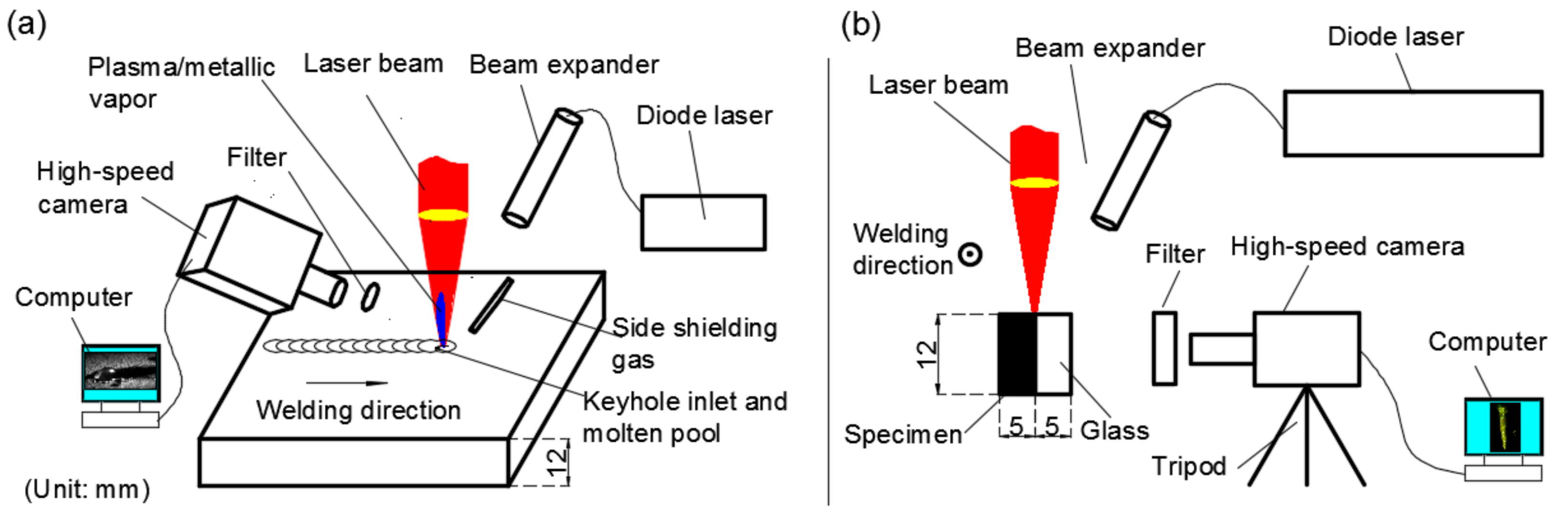

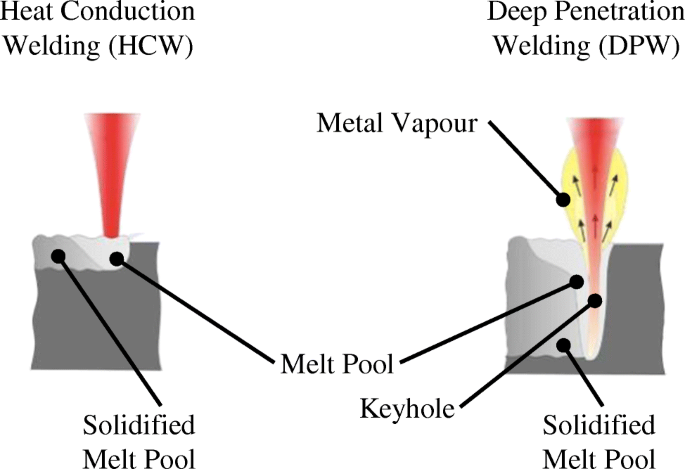

The process is frequently used in high volume applications using automation as in the automotive industry it is based on keyhole or penetration mode welding.

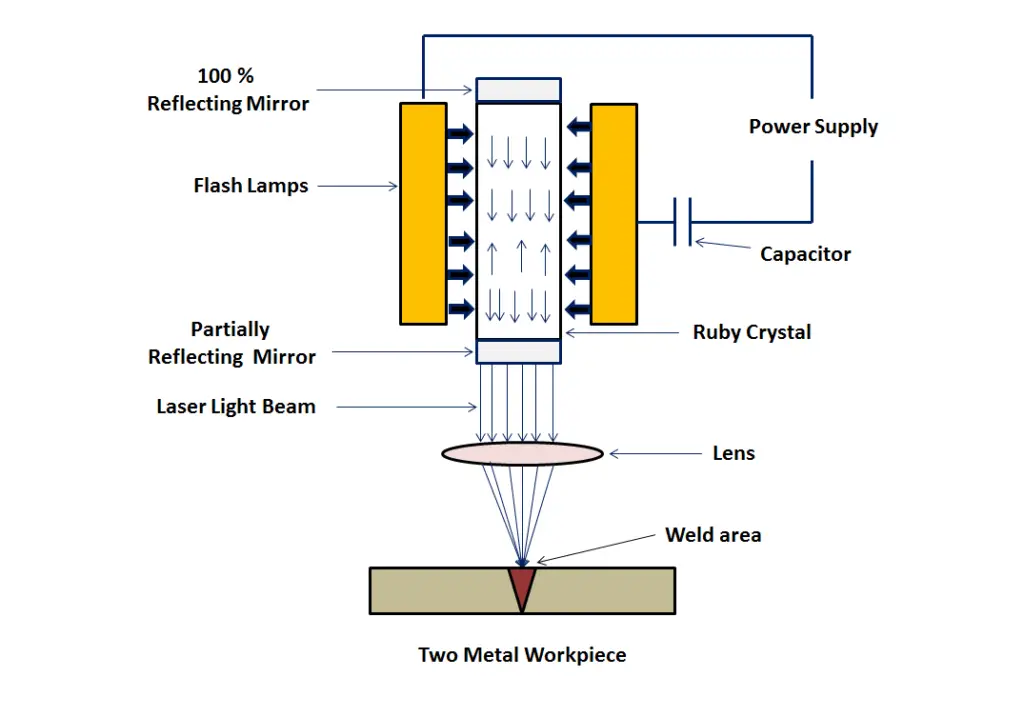

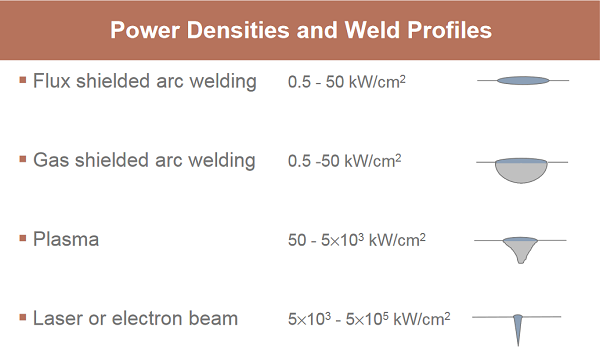

Laser beam welding lbw is a welding technique used to join pieces of metal or thermoplastics through the use of a laser the beam provides a concentrated heat source allowing for narrow deep welds and high welding rates.

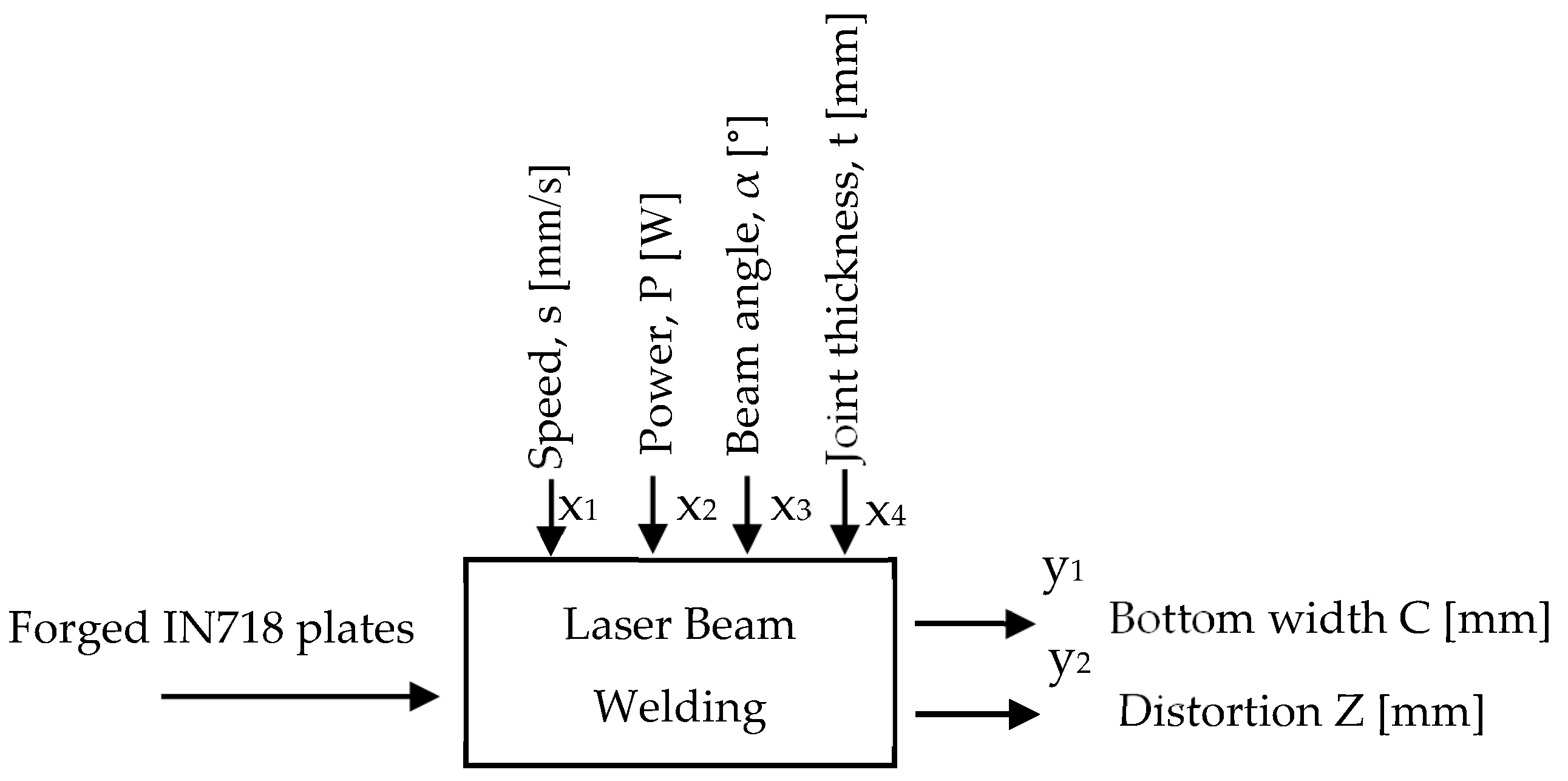

Process for quality control of laser beam welding and cutting download pdf info publication number us5272312a.