The thickness value is detected to micrometer accuracy using only a single sensor.

Laser thickness measurement principle.

Thickness measurement with laser.

Besides measuring the diameter of a round product laser based measuring devices can also be used for measuring a wall thickness.

The agt800 laser pipe pole measuring system is designed for measuring wall thickness.

Aluminium aluminium alloys lead bronze copper brass zinc die cast zinc tin.

The controller provides an editable expandable materials database.

It is a turnkey solution which utilizes two synchronized systems that moves in and out of the pipe on either side.

The eddy current principle enables the non destructive coating thickness measurement on non magnetic metal substrates eg.

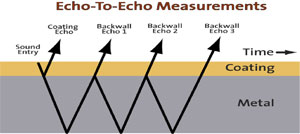

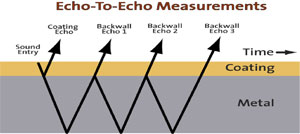

Ultrasonic wall thickness measurement operating principle ultrasound is a pressure wave with a frequency greater than the upper limit of human hearing approximately 20 khz.

A cmos array detects the position of the returned beam and is converted into a distance measurement.

The ar100 is one of the smallest laser measurement sensors in the world.

The basic components of a laser ultrasonic system are a generation laser a detection laser and a detector.

It provides fast and reliable thickness measurements and s p c.

The microtrak 3 tgs system uses the principle of laser triangulation to perform a one dimensional measurement of a target.

Reporting using the latest in laser triangulation technology.

The confocal chromatic measuring principle enables thickness measurements of transparent materials such as glass.

The measuring principle of the sikora laser series 2000 and laser series 6000 is based on diffraction analysis.

The laser thickness gauge with high response and high measurement resolution provides thickness measurement of the overall length including the top edge of the steel plate being conveyed.

Thickness is the simplest measurement done with laser sensors.

Laserlinc uses ultrasonic frequencies from 2 25 mhz to 50 mhz.

A fan shaped laser beam is directed onto a high resolution ccd line.

One sided thickness measurement of transparent materials.

It is a non contact technique used to measure materials thickness detect flaws and carry out materials characterization.

The laser thickness gauge is susceptible to the effect of mechani cal deformation due to temperature changes and vibra tion.

The laser projects a beam of light onto a surface which is then reflected back.

Laser ultrasonics uses lasers to generate and detect ultrasonic waves.

The eddy current principle is used in models marked with n or fn n non ferrous e g.

Direct benefits realized through these measurements include.

Laser measurement sensors measure thickness of materials.