Tib 2 particles were added into the lap joint.

Laser welding aluminum 6061.

The cover of a trumpf truflow laser resonator being laser welded in a laser welding cell in our farmington ct production facility.

The base alloy type in the question may vary but in essence the question remains the same.

Which filler wire is best for welding 6061 t6 aluminum 5356 or 4043.

What filler alloy should i use for welding this base material.

However aluminum poses difficulty in welding because of three main properties.

The beam source is a trum.

Common aluminum problems questions and answers.

I need to weld aluminum base alloy 6061 t6.

An aluminum alloy containing 5 percent magnesium 5356 generally is stronger and more ductile than 4043.

The present investigation was mainly concerned with characteristics of autogeneous laser butt welding of 2 x2009 mm thickness nonheat treatableaa5052 h12 aa5083 h12 and 2 x2009 mm 3 x2009 mm thickness heat treatableaa6061 t6aluminum alloys.

Fuerschbach on the weldability composition and hardness of pulsed and continuous nd yag laser welds in aluminium alloys 6061 5456 and 5086.

Metallurgical transactions b 1988.

There are several different types of lasers that work well with aluminum and often the use of a cover gas is prudent.

Both are acceptable for welding 6061 t6 but each has advantages and disadvantages depending on the application.

In this paper dissimilar metal joints of 6061 aluminum alloy and aluminum matrix composite material are investigated by laser welding.

The welding process microstructure and the corrosion properties of welding joints are examined.

Laser welding is widely used to join aluminum and its alloys.

1 thermal conductivity 2 surface reflectivity to infrared and near infrared laser radiation and 3 characteristics of the molten alloy including low viscosity and volatility of low boiling point alloying elements e g.

Laser conduction welding lcw 10 6 w cm 2 is comparatively stable and may offer an alternative means of welding traditionally difficult materials such as aluminum alloys.

The effect of laser welding parameters surface cleaning filler wire addition and backing strip on quality of laser welded joints was clarified using.

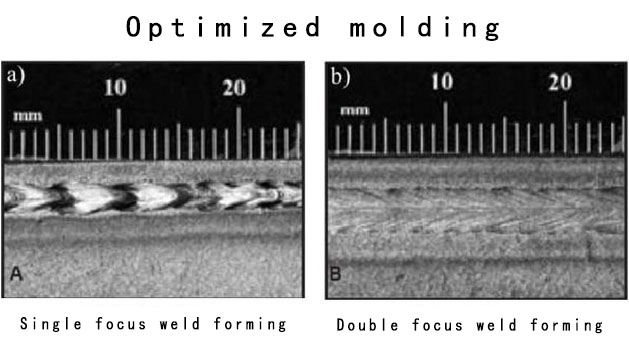

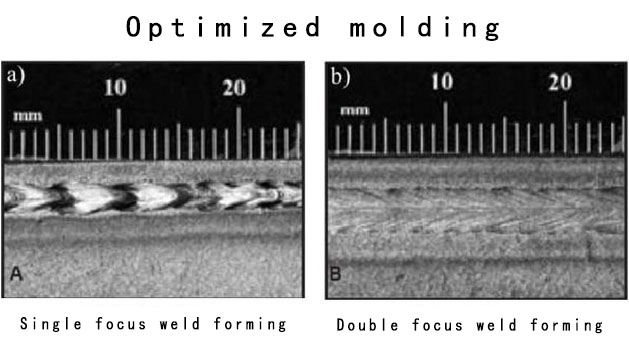

Laser welding of 6061 t6 crack sensitive aluminium based alloy with pulse shaping pulsed laser material processing requires the optimization of many parameters depending on the thermo physical properties of the material the environment laser and its process parameters i e.

The results demonstrate that the selected optimization process parameters are laser power 6 x2009 kw welding.

Laser and electron beam welding of al alloys.

Peak power pulse duration pulse energy pulse repetition rate.